CIP

Systems

About Clean-In-Place (CIP) Systems

Applications:

-

Food & Beverage Processing – including bottling, packaging, sanitation, and hygiene control

-

Pharmaceutical Manufacturing – for sterile environments, precise dosing, and contamination prevention

-

Dairy Plants – covering pasteurization, cleaning, production lines, and quality assurance

-

Chemical Processing – handling corrosive materials, complex reactions, and safety protocols

-

Breweries & Distilleries – for fermentation, cooling, filtration, and quality control processes

Essential

System Components

-

CIP Skids with Dosing Pumps – for automated cleaning processes

-

Storage Tanks – with hygienic and durable design

-

Heat Exchangers – ensuring efficient thermal transfer

-

Spray Balls & Rotary Jet Heads – for thorough internal cleaning

-

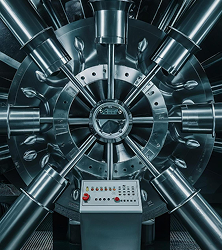

Control Panels (PLC or Manual Options) – with user-friendly interface

CIP Skids with Dosing Pumps

Storage Tanks and Heat Exchangers

Spray Balls and Rotary Jet Heads

Control Panels

Key Benefits of CIP Systems

-

Reduces Downtime & Labor Costs – significantly improving operational efficiency

-

Ensures Consistent Cleaning Quality – for every cycle, every time

-

Saves Water, Chemicals & Energy – helping reduce overall operating expenses

-

Hygienic & Regulatory-Compliant – meeting industry standards and requirements

-

Easy Integration with Existing Lines – for seamless and quick installation

Get the Best Deal for Your Global Trade Need

Looking to import or export quality agricultural or engineering products? Share your

requirements with us and receive a customized quote tailored to your needs — fast,

reliable, and hassle-free.